|

FlowerWindowBoxes.com is a custom millworks and windowbox company that custom fabricates, designs, and manufactures an exclusive line of architectural wood brackets. They can be custom made for homeowners, architects, builders, and remodelers, and we can match any DWG, DXF file, or drawing.

Specifications:

30" Projection x 36"High x 6" Thick (Rough, 5.5" Thick Smooth)

- 100% solid Red Western Cedar

- Ships FULLY ASSEMBLED to save time on installation

- Built to order in the USA by professional craftsmen

- Insect-resistant and does not absorb moisture

- Can be painted or stained to match home with any exterior oil base paint or stain (comes unfinished). Sealing helps keep the cedar from fading or developing cosmetic cracks over time

- Available in rough sawn and smooth sawn cedar

- Red western cedar comes in many color variations from reddish white to reddish browns your brackets and corbels may have beautiful color variations that differ from one product to the next

- Custom sizes available, Click for a FREE Estimate, email us your drawings at sales@flowerwindowboxes.com, or call us at 888-505-7715 today!

View Different Bracket Styles:

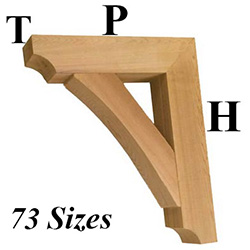

D01 Bracket

|

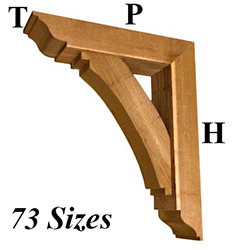

D02 Bracket

|

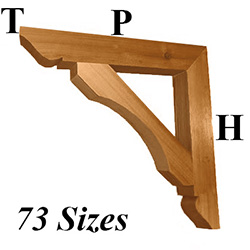

D03 Bracket

|

D04 Bracket

|

D05 Bracket

|

All Brackets

|

Related Products:

Cedar Gables

|

Cedar Corbels

|

Cedar Braces

|

Cedar Rafter Tails

|

Cedar Mantels

|

Cedar Shutters

|

Cedar Planters

|

Cedar Window Boxes

|

PVC Millworks

|

- Specifications:

30" Projection x 36"High x 5.5" Thick smooth (6"Thick rough)

(Solid, Paintable, Stainable)

CEDAR BRACKETS

Our cedar brackets are for decorative purposes. If planning to use structurally you MUST consult a professional contractor, engineer, or architect first to ensure you are ordering adequately sized brackets for your application. Also, we recommend using the professionals install method instead of our own since it will need to be specifically catered to your application. We do not load test our products but can provide cut sheets and specs on how these are constructed to your professionals so they can better understand the product and determine how to use them. If being used decoratively, however, then simply mount at the corresponding points in the diagram into load bearing studs hidden behind the wall. If masonry application, then you will need to install concrete anchors in he wall to receive the lag screws. Predrill a 3/16” hole in each spot of the bracket, then screw ¼” Timberlok lag screws through the bracket and the wall. You can sink the head of the screws 1” into the face of the bracket then fill the hole with wood putty or conceal with a wooden plug (not included) to hide the screw head. NOTE: If used outdoors we recommend sealing the wood to minimize the chance of it cracking over time. Sealing with oil-based paints (not latex), stain, or clear sealant is preferred. Large timbers can be subjected to small cracks over time nonetheless up to 1/16” wide without compromising the product.

|

|

|